Explore & Play

Discover interesting topics and solve the accompanying crossword puzzle.

Resin crossword | World of Resin and Diverse Uses

Table of Contents

Before you dive into the article, you can start by challenging yourself with the Resin crossword. If you’re already familiar with the topic, this will be a fun way to test your knowledge. However, if resin is a new subject for you, feel free to read through the article first to get more insight, and then return to the crossword to see how much you’ve learned. The choice is yours!

Resin Crossword

You can either fill in the crossword puzzle directly on this page or click the button in the bottom right corner to print it for free.

The Versatility of Resin in Our Daily Lives

Resin, both natural and synthetic, is a material that plays a crucial role in countless industries and daily-life products—from art and cosmetics to construction and technology. Whether it’s the amber resin used in jewelry or the epoxy resin that holds things together in construction, resins are indispensable to our world.

In this article, we will explore the fascinating journey of resin, from its origins in tree sap to its transformation into a versatile and essential material in modern life. Along the way, we’ll discuss the many uses of resin in art, manufacturing, and household products, touching on the diverse applications that make it so valuable.

1. The Origins of Resin: From Trees to Treasures

Resin has a long and rich history, starting as a sticky substance exuded by trees, which over time has transformed into valuable materials used in a variety of ways. Natural resins have been utilized for thousands of years, often revered for their aromatic properties, while synthetic resins have opened up new realms of possibilities in modern industry.

1.1 The Role of Trees in Resin Production

The journey of resin begins with trees, which produce it as a defense mechanism to heal wounds. Pines, firs, and other conifers are the primary sources of natural resin, which is extracted by tapping the trees. This process involves making a small incision in the tree’s bark, allowing the resin to ooze out and be collected for further processing.

This resin can then be used in various forms, such as raw gum or processed into products like varnishes, adhesives, and fragrances. The extraction of resin from trees has been practiced for centuries, and today, it remains an essential process for obtaining natural resins like Balsam, Gum, and Frankincense.

1.2 Natural Resins: Amber, Copal, and Myrrh

Among the most well-known natural resins are Amber, Copal, and Myrrh. Amber, formed from fossilized tree resin, is one of the most prized natural materials used in jewelry. Its warm, golden hue makes it highly sought after, and its use dates back to ancient civilizations. Copal, another type of resin, is often used in incense production, valued for its pleasant scent and grounding properties.

Myrrh, on the other hand, has been used for millennia in religious ceremonies and for medicinal purposes. It is an aromatic resin that was highly prized in the ancient world and is still used in perfumes, incense, and oils today.

1.3 Other Natural Resin Sources

In addition to Amber, Copal, and Myrrh, resins like Lac and Gum also play significant roles in cultural and commercial applications. Lac is a resin secreted by certain insects and is used to make Shellac, a natural coating and varnish. Gum resins, such as Balsam, have been used in both incense production and as healing agents, thanks to their therapeutic properties.

2. Synthetic Resins: Engineering the Future

While natural resins have been prized for centuries, synthetic resins such as Epoxy and Polyurethane have revolutionized industries with their diverse applications and versatility. These man-made resins are formulated in labs and factories, offering a range of properties that make them ideal for everything from adhesives to coatings.

2.1 The Rise of Synthetic Resins

The development of synthetic resins in the early 20th century marked a major shift in the world of materials. Chemists began experimenting with various compounds to create resins that could be produced in large quantities and adapted for different uses. As a result, synthetic resins quickly became a staple in manufacturing, offering a reliable alternative to their natural counterparts.

Synthetic resins are generally more durable and versatile than natural resins. They can be molded into various shapes, hardened into durable plastics, and used in a variety of industrial applications.

2.2 Epoxy and Polyurethane: The Powerhouses of Adhesives and Coatings

Among the most widely used synthetic resins are Epoxy and Polyurethane. Epoxy is known for its superior bonding strength, making it an ideal choice for adhesives, coatings, and even in the construction of airplanes and boats. Polyurethane, on the other hand, is prized for its flexibility and resistance to wear, which is why it’s commonly used in foams, coatings, and sealants.

Both of these resins are crucial in industries ranging from automotive to consumer goods, providing strength and durability in everything from furniture finishes to waterproof coatings.

2.3 Polyester and Silicone: Versatile Materials

Polyester and Silicone are two other widely used synthetic resins. Polyester is often used in the production of fibers, plastics, and resins for casting. Its low cost and ability to form rigid, durable materials make it an ideal option for a variety of products, from fabrics to packaging.

Silicone, while less rigid, is incredibly versatile, finding use in everything from molds and seals to electronic components. Its ability to withstand high temperatures and its non-reactivity make it a key material in a wide range of industrial and medical applications.

2.4 The Chemistry of Synthetic Resins

The process of creating synthetic resins involves a chemical reaction called polymerization, where smaller molecules (monomers) combine to form large, complex structures (polymers). These resins can then be shaped, hardened, or blended with other substances to create products suited to specific applications. The addition of Hardener speeds up the curing process, ensuring that the resin solidifies properly.

The combination of Solvents like Toluene and Terpene with resins allows them to dissolve and become workable, making it easier to apply them to surfaces. After application, these resins solidify, creating durable materials used in a variety of industries.

3. Resin in Everyday Products: From Art to Adhesives

From the art world to everyday household items, resin’s unique properties make it indispensable in a variety of products. Whether it’s used in high-end artwork or in the everyday products we use, resin continues to make an impact on our daily lives.

3.1 Resin in Art and Jewelry

Resin plays a major role in art, particularly in the creation of intricate jewelry pieces. Amber and Copal are two resins commonly used in the jewelry industry, where their natural beauty and durability make them ideal for crafting beautiful rings, necklaces, and bracelets.

Artists also use resins for creating coatings on paintings and sculptures, where they provide a glossy finish and protect the artwork from damage. Shellac and Lacquer, both derived from natural resins, are commonly used as varnishes in the art world, giving pieces a brilliant shine and added protection.

3.2 Resin in Construction and Design

In the construction and design industries, resins like Polyurethane and Epoxy are used for their durability and ability to bond various materials together. These resins are often used in adhesives, floor coatings, and waterproofing treatments, making them essential in both residential and commercial building projects.

Resin is also used in composite materials, where it is combined with other substances like glass fiber to create lightweight yet strong components for construction, automotive, and aerospace industries.

3.3 Resin in the Automotive and Electronics Industries

In the automotive industry, resins such as Epoxy and Polyester are used in the production of durable, lightweight components for vehicles. These materials provide strength and flexibility, allowing manufacturers to create parts that can withstand high levels of wear and tear.

Similarly, in the electronics industry, Silicone and Polyurethane are used to insulate and protect electronic components from moisture, heat, and other environmental factors. These resins ensure the longevity and reliability of products like phones, computers, and household appliances.

3.4 Adhesives and Sealants: Connecting the Dots

One of the most common applications for resins is in adhesives and sealants. Epoxy and Polyurethane are used extensively in both household and industrial adhesives due to their strong bonding properties. Silicone sealants are also crucial in creating waterproof barriers in windows, doors, and bathrooms, ensuring that moisture and air are kept at bay.

These resin-based adhesives and sealants are essential for the construction, automotive, and manufacturing industries, providing reliable, long-lasting bonds in a variety of applications.

4. The Process of Resin Creation and Application

The process of resin extraction, polymerization, and application is intricate, involving a range of specialized techniques and substances. Each step in this process is essential for transforming raw resin into a finished product that can be used in everything from art to industry.

4.1 From Tree Sap to Resin

The journey of resin begins when trees secrete sap in response to injury. This sap is then harvested and refined into usable resin. Once the resin is extracted, it undergoes various chemical processes to purify it and prepare it for different uses, whether that means turning it into Varnish, Shellac, or another form of resin.

4.2 The Role of Solvents and Hardening Agents

In order to make resins more workable, Solvents like Toluene and Terpene are often added to dissolve the resin and make it easier to apply. Once applied, Hardener is used to accelerate the curing process, ensuring that the resin sets properly and becomes durable.

These substances play a crucial role in ensuring that the resin can be used effectively in a wide range of applications, from coating furniture to binding materials together in construction.

4.3 Mold and Casting: Shaping Resin

In addition to being used as a coating or adhesive, resin can also be molded into specific shapes using Casting techniques. By pouring liquid resin into a mold and allowing it to harden, manufacturers can create intricate designs and components for everything from jewelry to automotive parts.

Epoxy and Polyester resins are commonly used for casting because of their ability to take on detailed shapes and their relatively low cost.

5. Conclusion: Embracing the Power of Resin in Modern Industry

Resin, whether natural or synthetic, is a key material that shapes the modern world. From its humble beginnings in tree sap to its transformation into indispensable products, resin has proven its versatility and importance in various industries.

As we’ve seen, resin is used in everything from jewelry and art to construction and electronics, demonstrating its ability to adapt to countless applications. The next time you encounter a resin-based product, whether it’s a shiny piece of amber jewelry or a durable epoxy coating, you’ll have a deeper appreciation for the role resin plays in our lives.

Call to Action

Before you finish, take a break and test your knowledge! Try solving our Resin-themed crossword to see how much you’ve learned from this article.

Share to...

I hope you enjoy the content.

Want to receive our daily crossword puzzle or article? Subscribe!

You may also be interested in

Share to…

Want to receive our daily crossword puzzle?

-

Jigsaw Puzzles

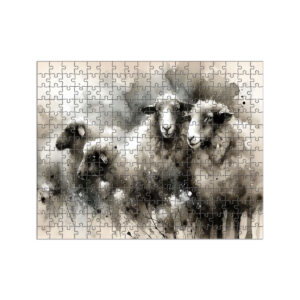

Enchanting Four Sheep Zodiac Jigsaw Puzzle 250 | 300 | 500 Pieces

kr 348,00 – kr 439,00Price range: kr 348,00 through kr 439,00 Select options This product has multiple variants. The options may be chosen on the product page -

Jigsaw Puzzles

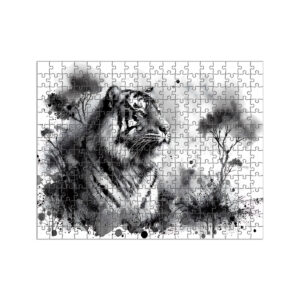

Zodiac Series Tiger Ink Puzzle – Black and White Art 250 | 300 | 500 Pieces

kr 348,00 – kr 439,00Price range: kr 348,00 through kr 439,00 Select options This product has multiple variants. The options may be chosen on the product page -

Jigsaw Puzzles

Trolltunga Abstract Jigsaw Puzzle 250 | 300 | 500 Pieces

kr 348,00 – kr 439,00Price range: kr 348,00 through kr 439,00 Select options This product has multiple variants. The options may be chosen on the product page